160 Year History of O’Brien Family Mason Contractors

~ By Ryan Michael O’Brien

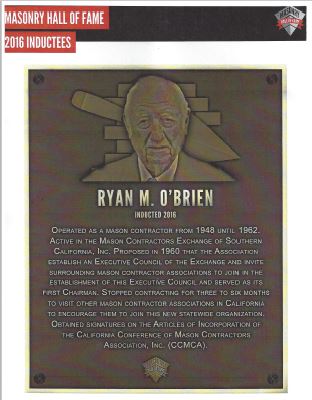

Receiving the Masonry Hall of Fame Award from the Mason Contractors Association of America on February 4, 2016, at the banquet closing the MCAA Convention was the culmination of the 160 years of the O’Briens in the masonry business and I am proud and thankful for receiving this award. As I am the last of the O’Brien family bricklayers and at 94 I do not think I will start up again. My advice to the young mason contractors is “keep the line tight and set the trig”.

My grandfather started his apprenticeship as a mason in 1854 in Saint Louis for Black Brothers Construction Company. I said mason not bricklayer as the mason placed the stone foundations, laid the brick walls, plastered the brick walls, installed the tile, roofed with slate shingles and punched holes in the slate for the handmade square nails with a little hammer with a flat nose. There were only three tradesmen, a mason, carpenter and plumber. All the rest of the construction workers were laborers.

My grandfather began contracting in 1865 in Wenona, Illinois, and made masons out of four of his sons including my dad. My uncle Jim started contracting as a Front Lumper in 1898 in New York and in the 1920’s was one the largest mason contractors in the Bronx. Tom Murphy a past President of the BMPIU worked for my Uncle Jim. The father of Dennis Day was a good friend of my Uncle Jim and during the summer when Dennis and his brother were out of school they worked as laborers for my Uncle. Dennis became an Irish signer and his brother became a dentist in Los Angeles. After the 1871 Chicago fire, the America bricklayers originated the five courses between headers which greatly increased production. In Europe headers were used extensively in the Flemish Bond were every other brick was a header and in the Dutch Bond every other course were headers which the German bricklayers called “binders”. A front lumper would hire good bricklayers and hod carriers and contract with the general contractor to lay the face brick on the front of the building for so much per thousand brick. The general contractor would employ the bricklayers and hod carriers to back up the work of the front Jumpers and provide all the materials. Just after the turn of the century, the BMPIU outlawed front lumping and most of the front lumpers became mason contractors.

My dad, Daniel Thomas O’Brien, was the first Delegate ever sent to the Bricklayer’s National Convention from California that was held in Trenton, New Jersey, in 1904. The Bricklayer’s Building in Washington, D.C. is named the Bowen Building and he was elected President at this 1904 Convention. My dad met some bricklayers from Boston at this Convention and told him of establishing a state-wide organization of the Bricklayer Local Unions in Massachusetts. He thought this would be a good idea for California. When he returned to California he scheduled a meeting of all the California Unions in Fresno and the California Bricklayers State Conference was established. He served as the Secretary-Treasurer until 1907. He became a mason contractor from 1913 till 1929.

Following World War II, I worked as a foreman and then obtained my California State Contractors Masonry License in 1947 at the age of twenty-five. I joined the Mason Contractors Exchange of Southern California and was the youngest member for the next ten years and now the oldest Honorary Member. I was President of the Exchange in 1951. In 1960 I contacted the local Mason Contractor Associations in Orange County, San Fernando Valley, Bakersfield and Ventura and established the Executive Council of the MCE with two representatives from each Association in order to negotiate with the eight Bricklayer Local Unions and the twenty-one Laborers Unions as a single Employer Bargaining Unit. I served as the Chairman of the Counsel for 1960 and 1961.

This worked so well that I proposed that we establish a State-wide organization and volunteered to stop contracting for three to six months to contact all the local associations in the State for just five hundred dollars a month to cover the gas for my Cessna 195 airplane. I obtained agreement from the San Diego Association, the Mason & Builders Association of San Francisco, the Sacramento Mason Contractors Association, and the San Jose Association. The California Conference of Mason Contractor Associations, Inc. was in business on January 1, 1963, and Incorporated in April, 1963. It is ironic that my Dad established the state-wide organization of bricklayers and fifty-nine years later I establish a state-wide organization of mason contractors.

When contracting I was the first to use a forklift on the job. I used a solid tired Towmotor on a project that was built on a paved parking lot. At that time in 1950 all common brick were delivered in a dump truck. I had to supply my own pallets and hire a flatbed truck to hall the pallets of brick to the job from the brick yard.

Tom and Mike Vinovich owned a Block Plant and Tom began building forklifts for use in the block plant with war surplus engines and supplies. I told Tom I would buy one if he could make a forklift that would reach twenty feet. I had six foot six scaffold frames which the third scaffold reached nineteen feet six inches. He built the twenty footer followed by hundreds more called the Champ Forklifts. The battle began with the Engineers Local Union which covered all of Southern California and Nevada and claimed jurisdiction over operation of the forklift.

In 1954 the Engineer’s Union and the Laborer’s Union met in Bal Harbor, Florida, to settle this dispute. They agreed that an engineer operate the lift but could not leave his seat to perform and work that was in the jurisdiction of the mason tenders. There must be a mason tender assigned to each forklift to direct the engineer were to place the materials. If any brick feel off the engineer was prohibited from leaving his seat to pick up the brick, only a mason tender was permitted to do this work. This ruling would eliminate all the savings derived for using a forklift. In Los Angeles we rejected this agreement and never agreed to be bound by any decision of the National Joint Board for the Settlement of Jurisdictional Disputes (Green Book) and continued to use mason tenders to operate the forklifts.

Our mason tender agreement was with the Southern California District Council of Laborers and this organization was under direct control of their International Union. I went to San Francisco to meet with the Vice President of the Laborers International. I took photos of my forklift showing the hydraulic remote, control on the grout and mortar hopper that allowed the forklift driver to fill the mortar boards and grout tubs without using a mason tender.

I had a member of the Mason & Builders Association along with their attorney come with me to meet with Vice President. He said the agreement has been made with the Engineers and we must abide by its terms. This did not seem right that the Laborers would give up the operation of the forklift so I went back to him the next day alone and there was a complete change. He told me things that I could not put in print but indicated the contractors should carry on the fight and he said “Go Getten Irish”. I assumed that he and the Laborer’s International Union could then tell the Engineers that they tried to enforce the agreement they made but the contractors refuse to agree and their hands are tied.

We therefore bypassed the District Council and negotiated a new collective bargaining agreement with the individual Local Unions which provided a clause that the operation of the forklift was the jurisdiction of the mason tender. West Coast Masonry owned by Cotton Purvis, a former Corsair pilot in the Navy had a project on Wilshire Blvd. about four blocks from the Engineer’s Office and was using forklifts. The Engineers placed pickets on the project and the District Council of Laborers supported the Engineers. We filed a claim with the NLRB and at the lOK Hearing the District Council of Laborers were a witness for the Engineers. In spite of both Unions maintaining that the Engineers had jurisdiction over the operation of the forklift we were successful in having the Hearing Officer rule that selecting the employ to operate the forklift in the masonry industry is solely vested in the Employer. This was the first lOK hearing ever held by the NLRB which was in 1957. The second lOK Hearing was in San Francisco against the Engineer’s Local Union that covered Northern California, Oregon, Washington, Alaska and Hawaii. This was in 1964 one year after the establishment of Mason Contractors Association of California and I was the Executive Vice President. In preparation for this hearing I sent out a letter to all mason contractors asking them fill in the number of forklifts they own and what Union does their operator belong to. At the hearing the letters were presented showing that over 350 forklifts owned by mason contractors were operated by members of the Laborers Unions.

The hearing officer asked me to wright the decision. As long as the Engineers were also making claims on the Tusky Hoist I added the Tusky Hoist along with the Forklift in masonry construction was in the jurisdiction of the Laborers. The project was the Laney College in Oakland and the General Contractor was Robert McKee who was an AGC member and signatory to the Engineers Agreement requiring him enforce the terms of this Agreement on all his subcontractors. The Engineers were now smart enough not to picket or approach the mason contractor or threaten a strike which would give an opportunity for the mason contractor to file a complaint with the NLRB. The mason contractor was E & S Masonry, Inc. and Ron Bennett the Regional Vice President of Region H represents this firm.

The new tactic of the Engineers was to hold Robert McKee liable for wages to pay three engineers who they claim should be operating the three forklifts on the project. Robert McKee had no worry because he just deducted these wages from E & S Masonry’s monthly check for work performed. After a few months his award was received and the Engineers were prohibited from making any further demand for the forklift on this project.The NLRB will never declare that their decision will cover all forklift jurisdictional disputes and will only cover this one particular project. This is a practice of most Federal Agencies. If they permanently settle these cases they would soon be out work.

When I was still contracting I was a target for the Engineers. Constructing a two story building addition to a Church building on Wilshire we were too high to use the forklift any further and my truck driver picked the forklift to take to another job. While towing the forklift and making the first turn a few blocks away both wheels on the forklift fell off in the busy street. Someone had removed all the lug bolts on the forklift wheels and took the nuts with them. I have a good idea who did the job and I think he was hoping that we would have a pallet of brick high in the air when the forklift turned over on the car filled Wilshire Blvd.

I always had plans to go back to contracting after the State Association was in good shape and I kept my forklifts and scaffold frames for over five years. There always was one more problem to solve and this went on for forty-seven years till 2009. During the 1980’s and 90’s the Officers were always asking when I was going to retire and I should bring someone in before I retire to teach him to maintain the operation, I always told them that I wanted to finish the Century. In 2000, we had a meeting in Palm Springs and to my surprise the Officers planned a Roast and Retirement Party. They had three comedians from Las Vegas and an Irish Colleen signing an Irish tune.

I told the Officers they misunderstood my statement on the Century. I meant “my century”, not the year 2000. I was only 78, and it was way too early to retire. I worked for another 9 years after the retirement party.